Monofilament Making Machine

Categories : Extrusion Lines For Filaments and Yarn

According to the processing purpose of monofilament, there are two types, one is two stages type (Equipped with stretching and annealing devices, the other is one stage type (Equipped with annealing device only).

PE & PP Monofilament Making Machine

Categories : Extrusion Lines For Filaments and Yarn

KS – MF100SC PE & PP MONOFILAMENT MAKING MACHINE WITH COMPUTER CONTROL SYSTEM

PE Monofilament Making Machine FCM-65

Categories : Industrial Knitting Machines

FCM-65 is the monofilament making machine with beam type winder which suites for HDPE raw material. It is suitable for our model SR-R, SR-RF & DR-R knitting machine. The winder is direct beam type so it doesn’t need to use the warping machine. Customer can save a working process of warping and also save the plant space.

High-Speed Zipper Profile Extruder INLL

Categories : Co-Extrusion Blown Film Machines

Zipper profile extrusion - Profile extruded by extruder directly into cooling water tank for formation. Profiles are closed and collected by carton or optional winder.

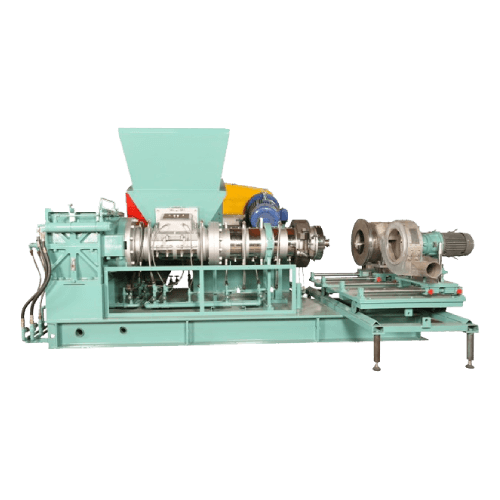

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Extruder usage for extruding and pellet producing after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind..

Feeder-Ruder Pellet Making Extruder

Categories : Feeders

This new model Feeder-Ruder Pellet Making Extruder usage for extruding and pellet making after Plastic or Rubber compound mixing in the Dispersion Kneader and conveying to the hopper of this machine. Pellets making method with mold Hot Face Cutting and Water ring cutting two kind.

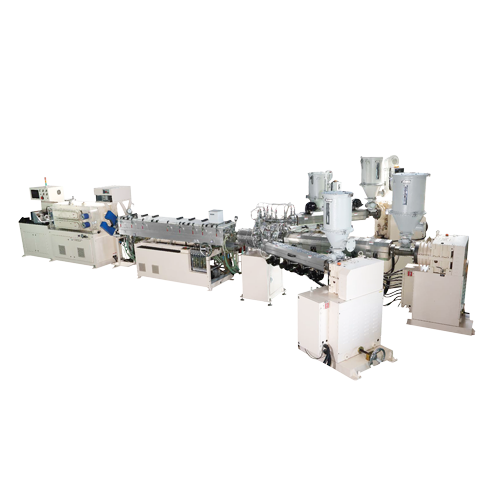

High Speed Multi-layer PE Tube Extruder and Cutting Machine EDC-16-05

Categories : Cutting Machines

-High speed & high output -High precision thickness control on each layer of tube -Simplified control -Quick tooling change by one operator -Closed loop cooling water circulation system -Caterpillar haul-off -Automatic outer diameter control unit (optional) -Low power consumption and high production efficiency

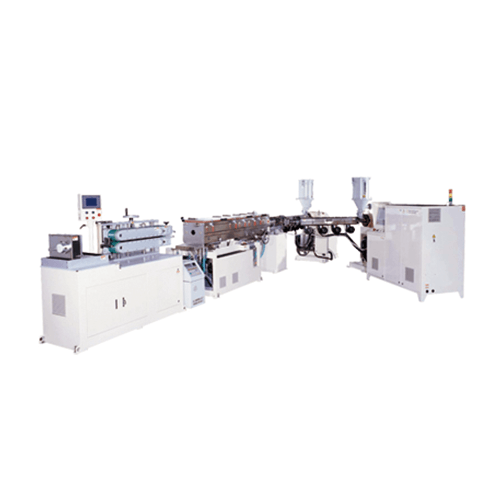

Two-Layer PE Tube Extruder & Cutting Machine EDC-08-02

Categories : Cutting Machines

-Two-layer extrusion tube can reduce material cost. (using: Pearl + PE/PE + Pigment) -The temperature controllers of different materials can be controlled individually. In this way, we can find out the best running condition on the materials both in running fluency and dissolubility. -The surface of co-extrusion tubes made by two-layer machine is more glossy than the surface of mono-layer tubes. -Using the same material on two-layer same material on two-layer co-extrusion can increase the water-resistance and anti-penetration of the materials for about 20~30%. (using: PE + Pigment. inner: recycled material.)

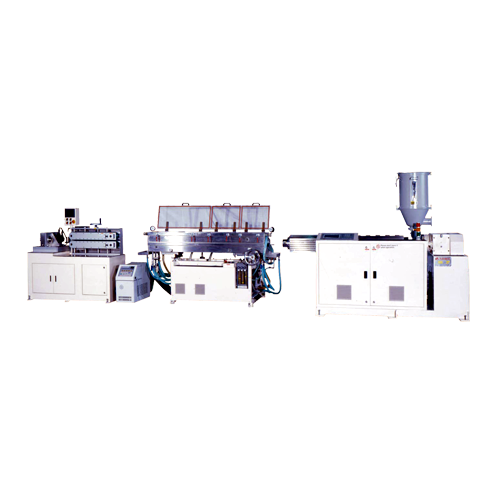

Twin Screw Parallel Counter-rotating Extruder

Categories : Twin Screw Extruders

•High specific output •Outstanding melt homogeneity •Maintenance-free, closed screw temperature control system •Wide processing range thanks to metering and stuffing device •Low wear thanks to low screw speed •Gentle politicizing thanks to longer screw and barrel Applications: - Hose - Pipe

Triple Extruder Machine (YSJ)

Categories : Extrusion Lamination Machines

● Working Material: BOPP film, CPP film, PET film, Cellophane, Aluminum foil, Paper, Non-woven fabric, PE film, Nylon film ● Resin: PP / LDPE / LLDPE / EVA / EAA / SURLYN

Mono-Layer PE Tube Extruder & Cutting Machine EDC-08-01

Categories : Cutting Machines

Extrusion is the first process of making PE tubes. This process ensures glossy surface, even thickness and well-balanced composition of plastic materials. For years of research and development, our remarkable achievements on LLDPE & LDPE melting, screw design, device of die head, material adoption, and surface treatment, together with size control by figuration and length restraint by encoder have produced valuable and high-quality tubes.

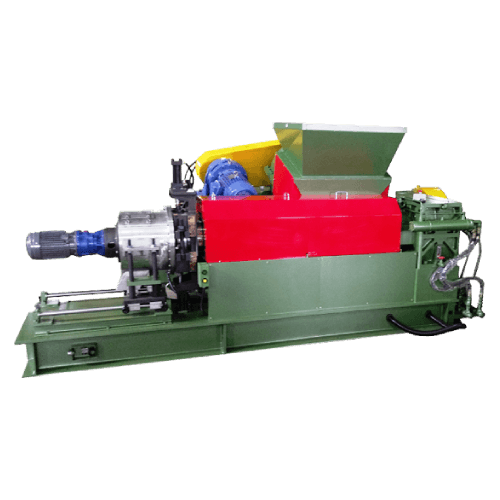

Twin Taper Screw Roller Head Extruder

Categories : Rubber Extrusion Lines

MACHINE FUNCTION: The Twin Taper Screws Roller Head Extruder consists of two tapered screws and two rollers,The machine is normally applied for processing to a dispersion kneader or an intensive mixer. The rubber material,mixed by a dispersion kneader or an intensive mixer,is then fed to the rollers through the two tapered screws.It calenders the material to a desired sheet form at a constant speed. The machine is designed and engineered for high speed sheet forming operations